Broiler Floor Raising System

Product: Automatic Broiler Pan Feeding System

Application: Broilers (one day old to 42 days old)

Specification: Customized according to customer’s breeding scale or chicken house size (Length*Width).

Raw Material: PP Plastic

Lifespan: 15-20 Years

Certificates: ISO 9001, SONCAP, CE.

Product introduction

The Broiler Floor Raising System is a poultry farming method that allows broiler chickens to be raised on the floor without the use of cages. This system is designed to provide a more natural environment for the chickens, allowing them to exhibit natural behaviors, move freely, and access food and water more easily.

| Equipment Parts | Automatic Broiler Pan Feeding System |

| Feed Silo | Material: hot dip galvanized Sheet thickness: 1.00mm Capacity: recommended feed amount for 2-3 days. |

| Main Feeding Line | The capability of conveying food: 1400KG/h Material: High-carbon manganese steel Sensor imported from Germany |

| Pan Feeding Line | Hot galvanized pipe contains the auger, which can transfer the feed from the vice feed hopper to the end of the house. Broiler automatic feeder pan capacity: 30-35 broilers/per feed pan |

| Drinking Line | Water pipe with drinking nipples. Nipple capacity: 8-10 broilers/per nipple. |

Key Features of the Broiler Floor Raising System

1. Open Floor Space: Unlike cage systems, the Broiler Floor Raising System provides chickens with unrestricted access to the floor, allowing them to move freely, explore their environment, and exhibit natural behaviors such as walking, running, and foraging.

2. Bedding Material: The floor of the poultry house is covered with a suitable bedding material, such as wood shavings, straw, or rice hulls, to provide a comfortable and clean surface for the chickens and facilitate waste management.

3. Feeding and Drinking Systems: Feeders and waterers are strategically placed throughout the floor area to ensure easy access to feed and water for all chickens, promoting uniform growth and minimizing competition.

4. Natural Light and Ventilation: The poultry house is designed to maximize natural light and ventilation, creating a comfortable and healthy environment for the chickens. Proper ventilation is crucial to control temperature, humidity, and air quality, ensuring optimal conditions for broiler growth and performance.

5. Health and Welfare: The Broiler Floor Raising System prioritizes the health and welfare of the chickens by providing a more natural and spacious environment, reducing stress, and promoting overall well-being. Regular monitoring, disease prevention measures, and biosecurity protocols are essential to maintain flock health and ensure a successful broiler raising operation.

Basic Chicken Equipment

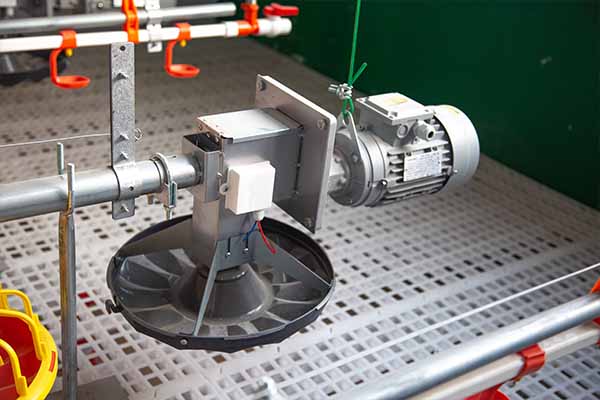

1.Pan feeding system for broiler

A: Vice Hopper

Capacity: 90-120KG

Material: Hot dip galvanized sheet

Thickness: 1.00mm

B: Driving Motor

Voltage: 380V 50hz 3 phases

Rated power: 0.75-1.1KW

Taiwan brand

C: Feed Sensor

Imported from German

D: Feeding Pan

Capacity: 30-35 broilers / per broiler feeder pan.

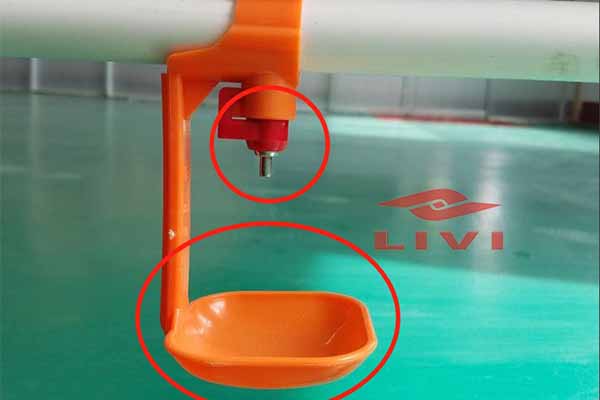

2. poultry drinking system

A: Pressure Regulator

Flexiable to adjust and a long lifespan

B: Water Pipe and Nipple Drinker

The water connection is sealed to prevent contamination. The drinking nipple is highly sensitive and rotates 360 degrees.

Advantages of the Broiler Floor Raising System

Natural Behavior: Allows chickens to exhibit natural behaviors and movements, contributing to their physical and psychological well-being.

Accessibility: Facilitates easy access to feed and water, promoting uniform growth and reducing competition among chickens.

Flexibility: Suitable for various flock sizes and farm layouts, allowing for customization and adaptation to specific farming conditions and requirements.

Environmental Benefits: May offer environmental benefits by reducing the use of cages and promoting more sustainable and ethical farming practices.

Comparison with Broiler Cage System

| Criteria | Broiler Floor Raising System | Cage Farming for Broilers |

| Stocking Density | Lower density, more space for chickens to move and roam. | Higher density, limited space for each chicken due to cage confinement. |

| Growth Efficiency | Potentially slower growth rate due to increased physical activity and natural behaviors. | Typically faster growth rate due to controlled environment and feed management. |

| Welfare Consideration | Improved welfare with natural behaviors like foraging, dust bathing, and roaming. | Restricted natural behaviors, potential for stress and welfare concerns due to confinement. |

| Input Costs | Higher initial investment for infrastructure and land. | Lower initial investment for cage systems but may incur higher operational costs for feed and utilities. |

| Health Consideration | Potentially reduced risk of certain diseases due to lower stocking density and natural behaviors. | Higher risk of diseases and health issues due to higher stocking density and confinement. |

What can livi Machinery bring to you?

Pre-Sales Services:

- Professional Consultation: Our professional design team is ready to provide you with design solutions within 24 hours.

- Tailored Design Solutions: provides customized design solutions that optimize space, enhance workflow efficiency.

After-Sales Services:

- Installation Services:Installation drawings and site installation

- Transportation Services:livi Machinery will handle import and export problems for you.

- Maintenance and Technical Support:We’re here to assist you with technical inquiries, farming advice, and emergencies throughout the year.

FAQ

What kind of chicken products do you have?

Main chicken products: chicken cages

Supporting automated chicken equipment: egg collection equipment, chicken manure removal equipment, chicken feeding equipment, and environmental control equipment.

Corollary equipments: incubator, egg tray machine, feather removal machine, egg grading machine, pellet machine, heating system

How to obtain the chicken design scheme?

All you need to do is tell us your estimated size and coop size. We will provide you with free breeding design solutions. You just need to buy our products.

How to transport chicken equipment after purchasing?

All you need to do is just make the payment, and we’ll handle the rest. including arranging shipping to South Africa and delivering right to your farm. Let us handle your imports without any stress or worries.

How to pay after purchasing chicken equipment?

Our payment terms are as follows: please make the payment before delivery. You can pay a 30% deposit through T/T or Western Union. Then, you pay the rest before we load your order from our factory.

How to install chicken equipment?

We offer two options for installation services:

1. Professional Installation: We will send 2 engineers from Nigeria or Ghana to conduct the on-site installation. This service includes 20 days of installation support, along with training and guidance for your team. There would be an additional cost of 6,000 USD for this option.

2. Installation by yourself:

(1) We will provide all of the installation drawings including but not limited to foundation drawing, installation drawing, electrical connection drawing, etc.

(2) Online WhatsApp/WeChat group with you, your engineer, our engineer, and an after-sales workmate. If you have any questions, we can discuss them online, this is our permanent work.

(3) In this way you can install the equipment by yourself or by finding a local engineer who understands the drawings.

What’s the address of your company?

Our company is located in China. But our equipment has been selling very well in South Africa and we have many satisfied customers there.