Livi Machinery offers a customized Uganda Poultry Farm Design for clients aiming to establish a large-scale, automated egg production facility. This project is designed for 150,000 layer chickens, combining modern technology, efficient layout, and advanced equipment. With professional planning and durable Layer Farm Cages For 150000 Chickens, the farm ensures high productivity and long-term sustainability.

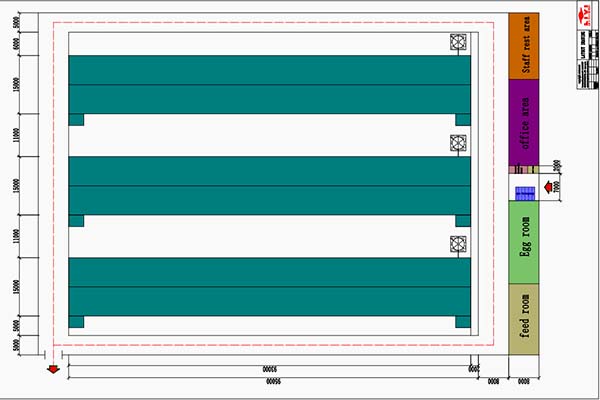

Overall Farm Layout

The farm covers an area of 120m x 88m, strategically divided into production, storage, and living areas. The design focuses on functionality, ease of management, and biosecurity.

| Area | Dimensions | Function |

|---|---|---|

| 3 Layer Houses | 95m x 15m each | Housing chickens with modern cage systems |

| Egg Storage | Custom size | Safe storage and handling of fresh eggs |

| Feed Warehouse | Custom size | Bulk feed storage for continuous supply |

| Office & Admin Zone | Custom size | Management, supervision, record-keeping |

| Staff Living Quarters | Custom size | Accommodation and welfare for employees |

If you are planning to start or upgrade your own poultry business, you can leave us a message on our website. Our team will provide you with a free consultation and a tailored farm design proposal.

Layer Farm Cages For 150000 Chickens

At the heart of the poultry farm are the H-type layer cages, built to maximize bird comfort and egg production efficiency.

- Cage Size: 1200 × 625 × 480 mm

- Structure: 4-tier design, durable galvanized steel

- Capacity: 144 chickens per cage set

- Total Birds: 150,000 layers across 3 houses

These automatic poultry cages in Uganda provide uniform feeding, optimal stocking density, and minimal egg breakage.

Uganda Poultry Farm Design for 150,000 Laying Hens

Modern Automated Layer Battery Cages Systems

To achieve a fully automated layer farm in Uganda, the design integrates advanced equipment that reduces labor costs and increases efficiency:

- Automatic Egg Collection System – ensures clean, fast egg handling

- Manure Removal System – keeps houses hygienic and disease-free

- Feeding System – precise and uniform feed distribution

- Ventilation Equipment – stable indoor climate for healthier flocks

- Lighting & Control System – optimized for high egg production rates

Key Benefits of Livi’s Uganda Poultry Farm Design

- High Efficiency: Compact yet scalable design for long-term growth

- Cost Savings: Automation reduces reliance on manual labor

- Better Biosecurity: Cleaner environment minimizes disease risk

- Sustainable Operations: Manure management and ventilation protect both birds and workers

- Market Competitiveness: Reliable, large-scale egg production for Uganda’s growing demand

Conclusion

This Uganda Poultry Farm Design demonstrates how science-driven planning and modern equipment can transform poultry farming in Africa. With Layer Farm Cages For 150000 Chickens and advanced automation, the client will benefit from high egg output, reduced operational costs, and long-term profitability.

💡 Are you considering building your own large-scale poultry farm? Contact us today and leave a message on our website. Our engineers will help you design the right solution for your farm in Uganda or anywhere else in Africa.